Cranes and hoists are essential tools in many industrial applications. They make it easy to move bulky or heavy materials around the worksite, which increases efficiency and improves safety.

Given their vital role, it is important to maintain them properly. Otherwise, they may fail unexpectedly, which can lead to significant downtime and/or serious injury. That’s why all cranes and hoists should be inspected at least every 12 months for signs of failure. However, you should keep an eye out for signs of failure between annual inspections.

The Occupational Safety and Health Administration (OSHA) is an organization that focuses on ensuring safe and healthful working conditions in various job fields. Regarding work that utilizes cranes and hoists, they provide guidelines on what to look out for in the equipment that may indicate it needs repairs.

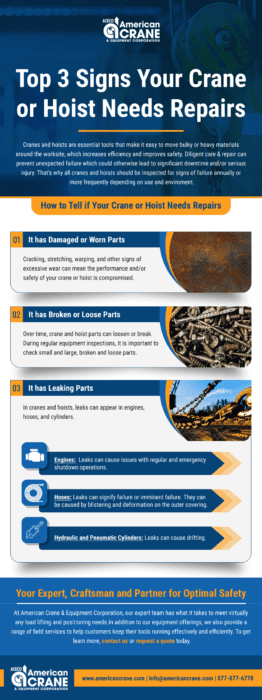

Below, we highlight the top three signs your crane or hoist may need repairs.

1. It has damaged or worn parts.

Cracking, stretching, warping, and other signs of excessive wear can mean the performance and/or safety of your crane or hoist is compromised. These conditions can appear on various components of cranes and hoists, including bearings, chains, pins, rollers, shafts, sheaves and drums, and welds. It is vital to regularly check all of these components to ensure they are not damaged or worn.

In wet or humid environments, there is also a risk that metal components will corrode. As this can significantly diminish the integrity of the crane or

hoist assembly, it is also important to look out for corroded parts.

Whether a part is damaged or worn, it is important to repair or replace it quickly before it can lead to equipment failure.

2. It has broken or loose parts.

Over time, crane and hoist parts can loosen or break. If left unchecked, the loose or broken parts may affect equipment performance and, eventually, cause catastrophic failure. For example, in cranes and hoists that use chains, the chain component eventually gets worn out. If it breaks during operation, heavy or bulky materials may fall on employees or equipment.

During regular equipment inspections, it is important to check both small and large parts. The former can be easy to overlook. Additionally, look for both broken and loose parts. While the broken parts may be obvious, the loose parts may go unnoticed until they fall out completely.

3. It has leaking parts.

In cranes and hoists, leaks can appear in engines, hoses, and cylinders. If and when they occur, they should be addressed immediately as they can lead to serious operational and safety concerns.

In cranes and hoists, leaks can appear in engines, hoses, and cylinders. If and when they occur, they should be addressed immediately as they can lead to serious operational and safety concerns.

- In engines, leaks can cause issues with regular and emergency shutdown operations.

- In hoses, leaks can signify failure or imminent failure. They can be caused by blistering and deformation on the outer covering.

- In hydraulic and pneumatic cylinders, leaks can cause drifting. They can be caused by dents, nicks, scores, and other damage to the rods, barrels, eyes, or joints.

Partner With ACECO for Your Crane and Hoist Repair Needs

Want to learn more about how to tell whether your crane or hoist needs repairs? Turn to the experts at ACECO!

At American Crane & Equipment Corporation, we manufacture standard and custom cranes, hoists, and other material handling equipment for various industries and applications. Our expert team has what it takes to meet virtually any load lifting and positioning needs.

In addition to our equipment offerings, we also provide a range of field services to help customers keep their tools running effectively and efficiently. These include:

- Repair

- Rebuilding

- Modification

- Upgrading

- Inspection

- Load testing

- Preventative maintenance

- Installation

- Retrofitting

For more information about our material handling products and services, contact us today. To discuss your equipment requirements with one of our representatives, request a quote.