Single Failure-Proof Cranes: Your Assurance of Reliability

Single Failure-Proof Cranes

For over 50 years, American Crane and Equipment Corporation has been designing and manufacturing sophisticated equipment for the nuclear industry to handle their low-level nuclear power plant waste.

In the early 1990s, ACECO solidified our future in the nuclear industry with the Implementation of ACECO’s 10 CFR 50 Appendix B/NQA-1 QA program. ACECO was one of the first crane companies in the country to achieve this milestone.

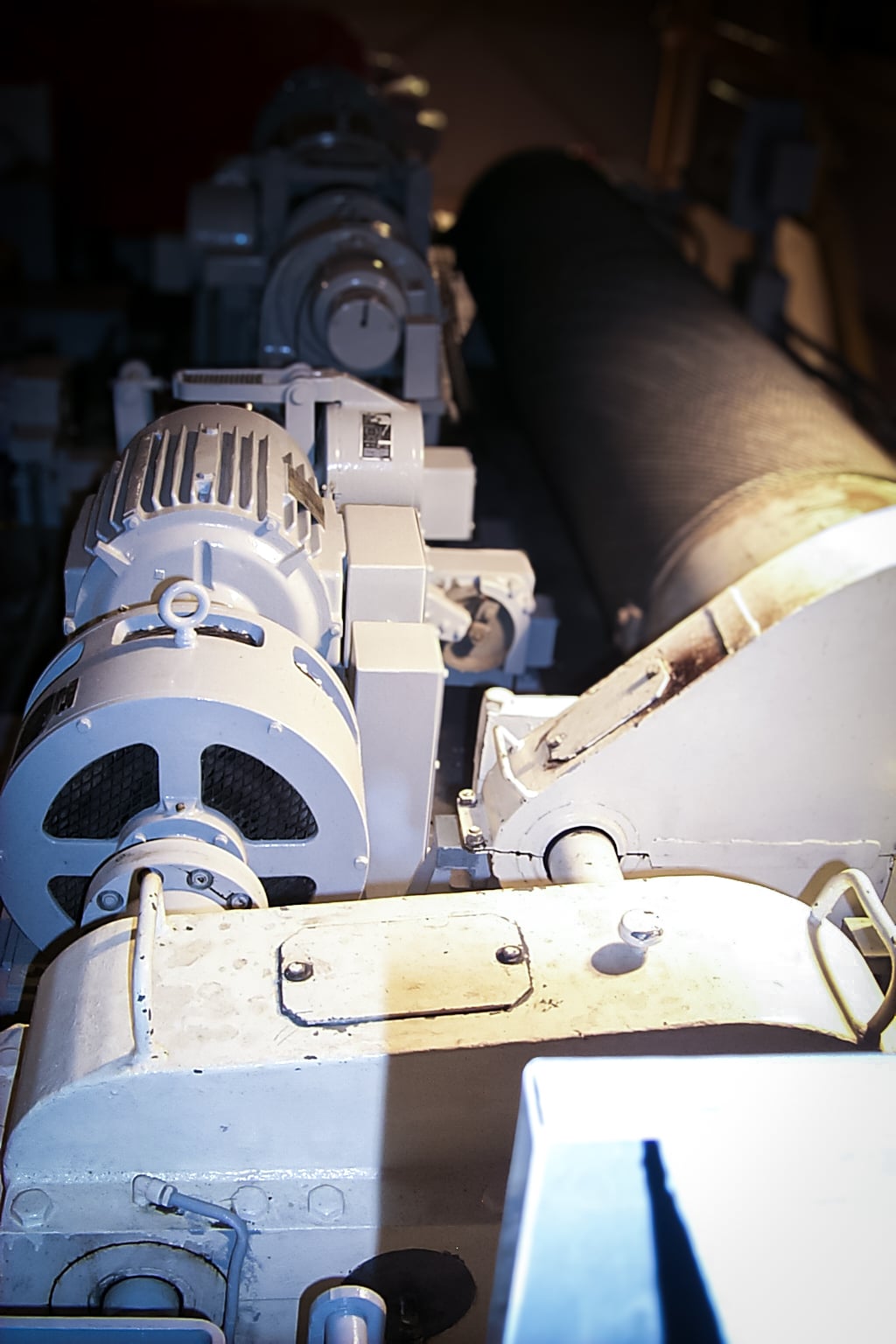

Single failure-proof cranes lift and transport critical loads, remaining functional even if a component in the hoist load path fails. These cranes rely on redundant designs so that the failure of a single component in the hoist load path will not result in a drop or uncontrolled descent of the lifted load. This design offers maximum security, preventing damage to the load or nearby equipment and infrastructure. The aerospace and nuclear industries rely on single failure-proof cranes to prevent disastrous consequences when carrying critical loads like spacecraft equipment, satellites, and aircraft components, while the nuclear industry relies on SFP cranes to move large casks of nuclear waste, delicate items, or oversized loads that cannot be dropped under any circumstances.

Advancing Aerospace with Single Failure-Proof Cranes

Applications of Failure-Proof Cranes in the Aerospace / Aviation Industry

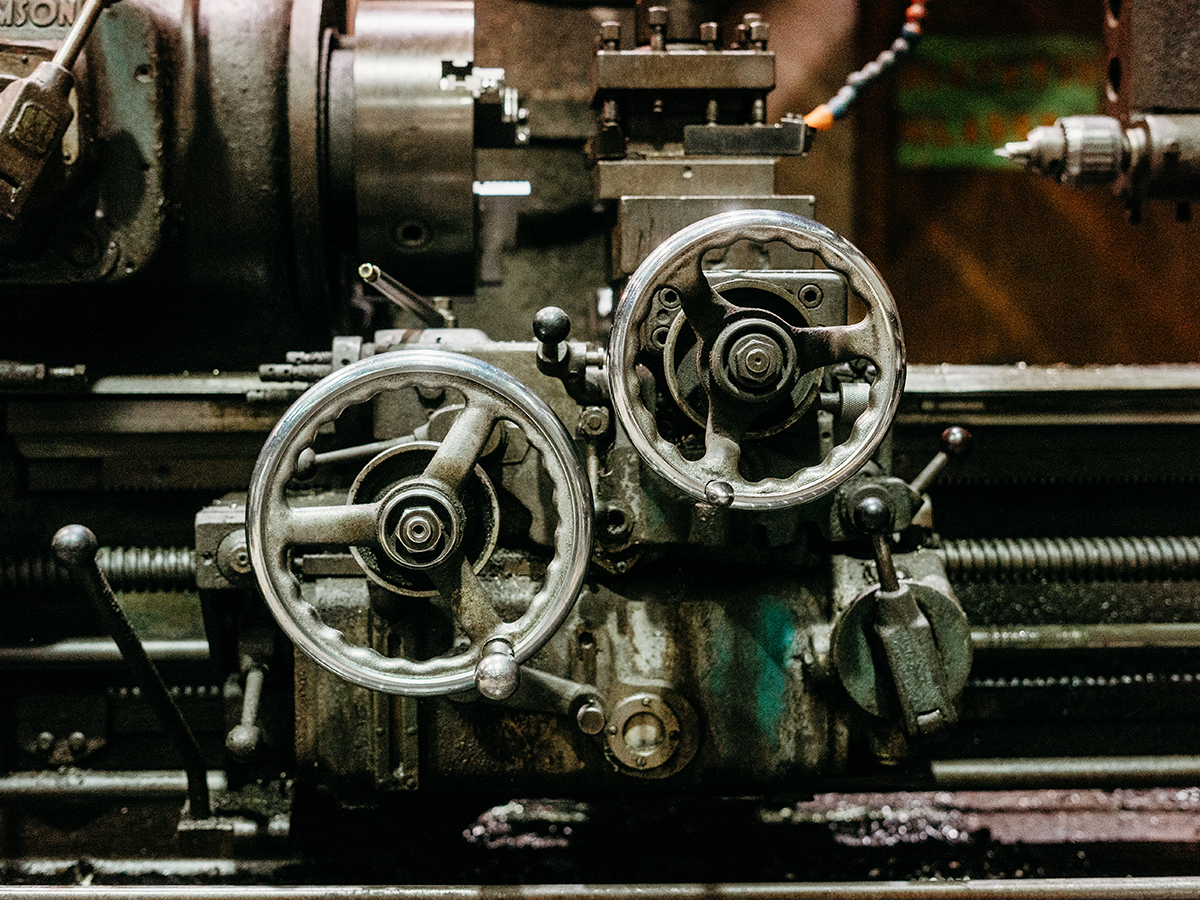

Single failure-proof cranes have various performance and safety features to assist in critical lifting applications in the aerospace industry. Our aerospace single failure proof cranes have enhanced safety and redundant design features including an emergency caliper-style hoist drum brake, misreeving protection to detect wire rope slackness, and overspeed protection directly applied to the drum shaft. They also have hook isolation that limits microamperes to 70 per 1000 volts and redundant hoist reeving to prevent load drop if the wire rope fails.

Our SFP crane performance features include a high-accuracy positioning system, two portable stations and remote master control, and flux vector AFD controls to hold a load in place at zero speed. Its weigh scale system provides accuracy within 0.5% and electromagnetic interference (EMI) filtration to shield the power system from external EMI.

The following features make ACECO’s single failure-proof cranes ideal for critical lifting in the aerospace industry:

- Complex aircraft assembly & handling.

- Transporting loads over critical parts.

- Lifting time-sensitive equipment for space flight manufacturing.

- Transporting satellites & other valuable equipment.

Advancing Nuclear Operations with SFP Crane Technology

Applications of Single Failure-Proof Cranes in the Nuclear Industry

Single failure-proof cranes play a vital role in the nuclear industry. Our overhead cranes have single failure proof and enhanced safety design features to prevent catastrophe when handling critical equipment. We are capable of designing a custom SFP crane for integration in new or existing facilities, as well as tailoring them for seismic specifications based on your site.

Our SFP cranes include remote operator controls for ALARA concerns, flux vector controls via infinitely variable speed frequency drives, triple redundant holding brakes, and redundant hoisting machinery and reeving systems. Our cranes come with protection from overload, wire rope mis-spooling, two blocking, and load hang up concerns.

Single failure-proof cranes from ACECO use an NRC-accepted design and comply with NUREG 0554 and 0612, as well as ASME NOG-1. They are ideal for lifting radioactive casks in the nuclear power industry.

Precision and Safety in Lifting: Single Failure-Proof Cranes

Single Failure-Proof Crane Features

Single failure-proof cranes offer the safety features necessary for critical equipment handling. We perform load testing per OSHA regulations to ensure reliable performance. All ACECO equipment used in nuclear applications must address our 18-point Quality Assurance (QA) program. Our single failure-proof cranes for nuclear applications also comply with relevant NUREG and ASME standards.

ACECO’s single failure-proof cranes are the ideal choice for critical lifting applications in the nuclear industry. With their unmatched safety and reliability features, these cranes can operate flawlessly even in the most demanding environments. ACECO’s cranes are engineered to handle heavy loads and work efficiently in tight spaces, making them an essential asset for any nuclear facility. When it comes to critical lifting, there’s no better choice than ACECO’s single failure-proof cranes.

- Redundant Reeving & Hoisting.

- Triple Redundant Holding Brakes & Emergency Hoist Brakes.

- Two Blocking, Overload, Overspeed, Mis-Spooling, & Load Hang-Up Protection.

- NRC-Accepted Design.

- Flux Vector for Infinitely Variable Frequency Drives.

- Seismic Design Per Site.

Reliable Below-the-Hook Solutions from ACECO

Single Failure-Proof Cranes from American Crane & Equipment Corporation

Single failure-proof cranes offer reliable service for critical load applications. The aerospace and nuclear industries depend on single failure-proof industrial and overhead cranes for safely handling expensive and/or time-sensitive components. American Crane’s single failure-proof cranes offer various features to enhance safety and performance in these critical applications.

Contact us to learn more about our single failure-proof cranes for critical loads, or request a quote today.