Magnetek

Magnetek VFD Motor Control Products

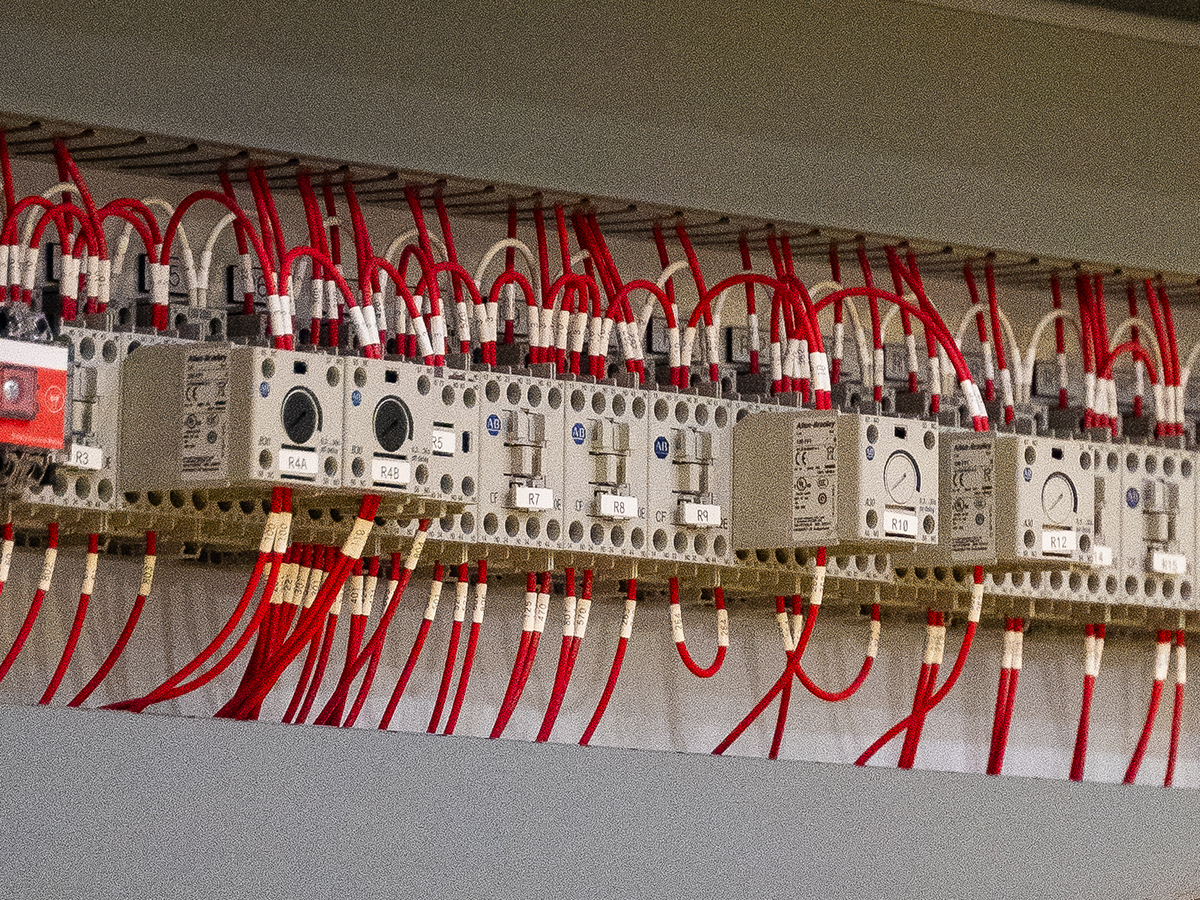

Magnetek VFDA variable frequency drive (VFD) is an AC motor controller that operates a corresponding electric motor at adjustable speeds to ensure managed and effortless operation. VFDs modify the iteration of the engine through frequency and voltage supply alterations to adjust the revolutions per minute (RPMs). To do this, a VFD will convert three-phase AC voltage to DC through diodes, and then clean the DC with a capacitor. Next, it will convert the DC voltage back to AC with transistors acting as switches to adjust the frequency and precisely control motor speed.

VFD motor control products can be designed for specialized functionality within electric hoists, lifting systems, and overhead cranes. These VFDs utilize a microprocessor to program specific tasks for hoisting equipment. At American Crane & Equipment Corporation, we are pleased to offer crane-specific Magnetek components including IMPULSE drives and brake resistors for optimal crane performance. Magnetek is a leading supplier of drives and control systems for overhead cranes and related machinery, with decades of experience in the material handling industry.

Magnetek’s Crane-Specific VFDs

When choosing a VFD for your crane, Magnetek’s VFDs are better suited than general-purpose varieties. The range of motion and gravitational forces that influence crane applications are quite dissimilar to the operating conditions of pumps and fans. In addition to varying speed options, crane-specific VFDs can significantly impact your operation’s safety and productivity.

Magnetek designs VFDs to fit specific needs for optimal crane operations with easy setup and greater versatility in speed modification. VFDs allow for smooth, deliberate acceleration and deceleration through drives and brakes, respectively. Both systems provide quick and precise lifting and positioning, all while conserving energy compared to soft-starters and contractors.

- CM motor, brake, control, and gearing components

- Hooks and lower blocks

- Chains, wires, and hoists

- Automation technology

American Crane: Your Destination for High-Quality Magnetek VFDs

Magnetek VFD Motor Control Products at American Crane

Magnetek VFDs are considered to be dependable “brains inside the crane,” utilizing advanced software to provide safe, high-performance positioning and hoisting. Their drives and brake resistors offer careful, efficient control over crane motion and positioning, with continuous monitoring to make sure the cranes are functioning reliably.

- Advanced Software

- High-Performance

- Safe & Efficient

Magnetek Drives: AC IMPULSE Drives

AC IMPULSE Drives enhance crane performance with advanced control and reduced maintenance, extending equipment lifespan.

Magnetek Brakes: Dynamic Braking Resistors

Our dynamic braking resistors extend brake lining life, convert regenerative energy to heat, and improve crane deceleration control.

Providing High-Performance Magnetek Equipment

American Crane is your supplier for Magnetek products.

Magnetek VFDs and brakes are particularly beneficial to the material handling industry thanks to their enhanced safety features, superior control, and competitive prices. Along with Magnetek’s high-quality components, ACECO offers comprehensive custom manufacturing, installation, inspection, training, and repair services. Contact us for more information on the Magnetek equipment that we carry as part of our catalog of over 40,000 components, or request a quote today.