Ensuring Optimal Efficiency and Safety in Metal Finishing and Processing

Finishing Mill Cranes & Hoist Systems

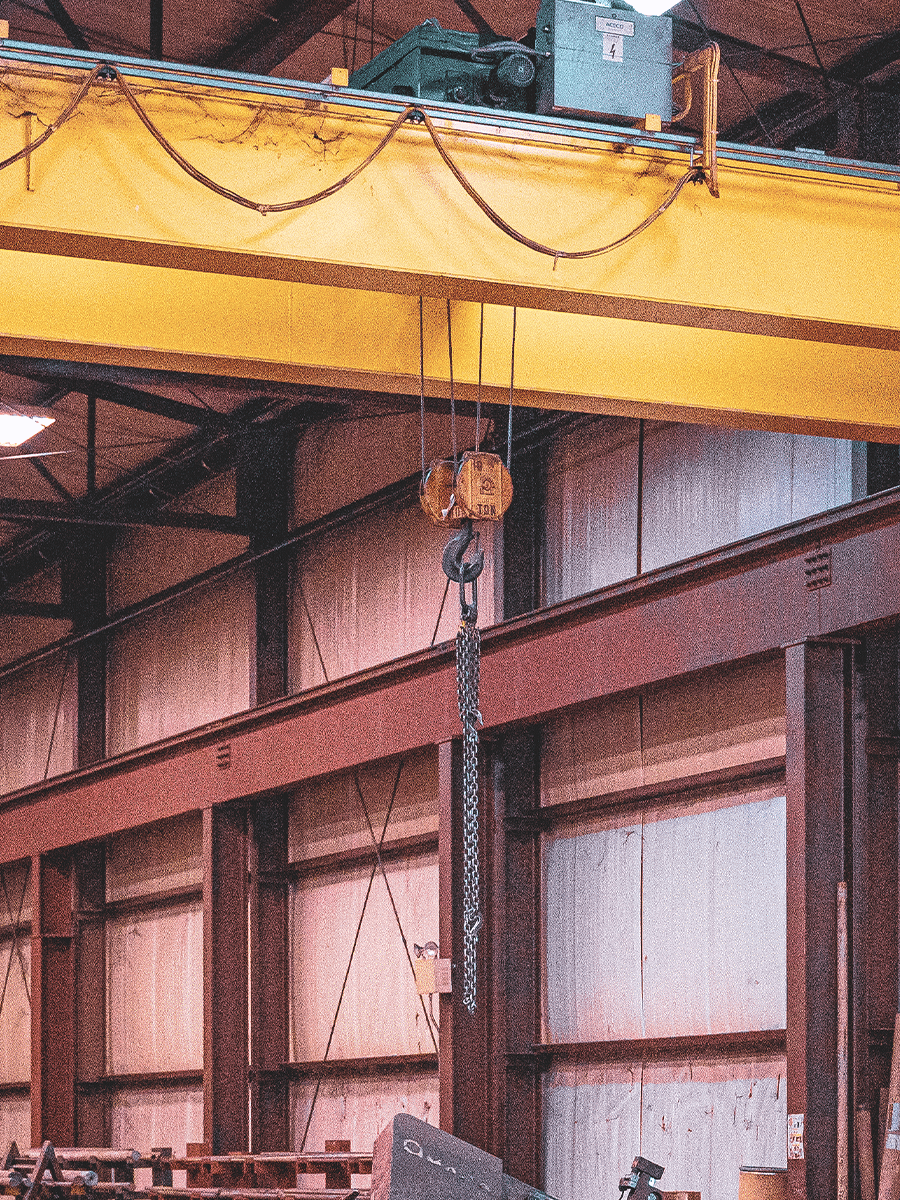

Metal finishing mills require more than high-quality finishing equipment to ensure materials leave the plant in top condition and all processes are conducted safely and efficiently; they also require high-performing, reliable material handling equipment.

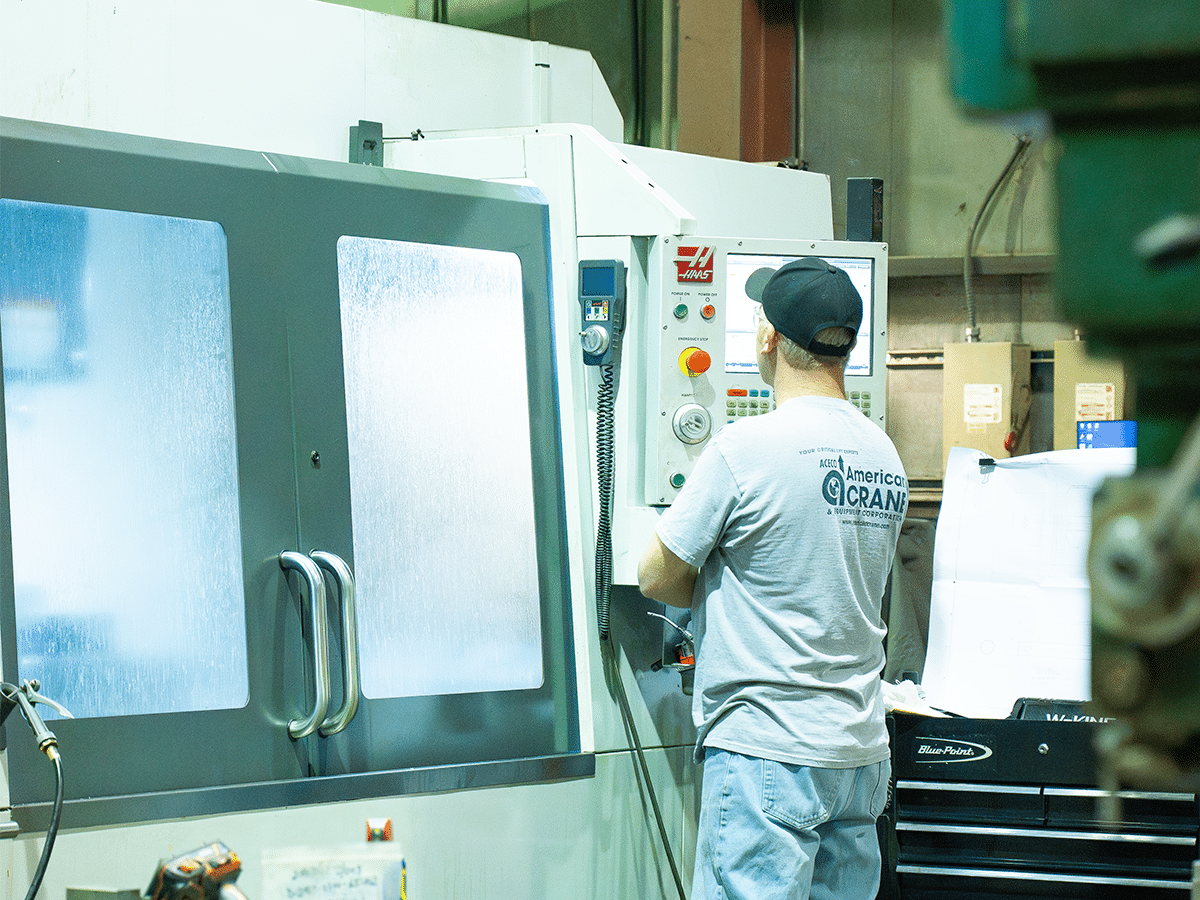

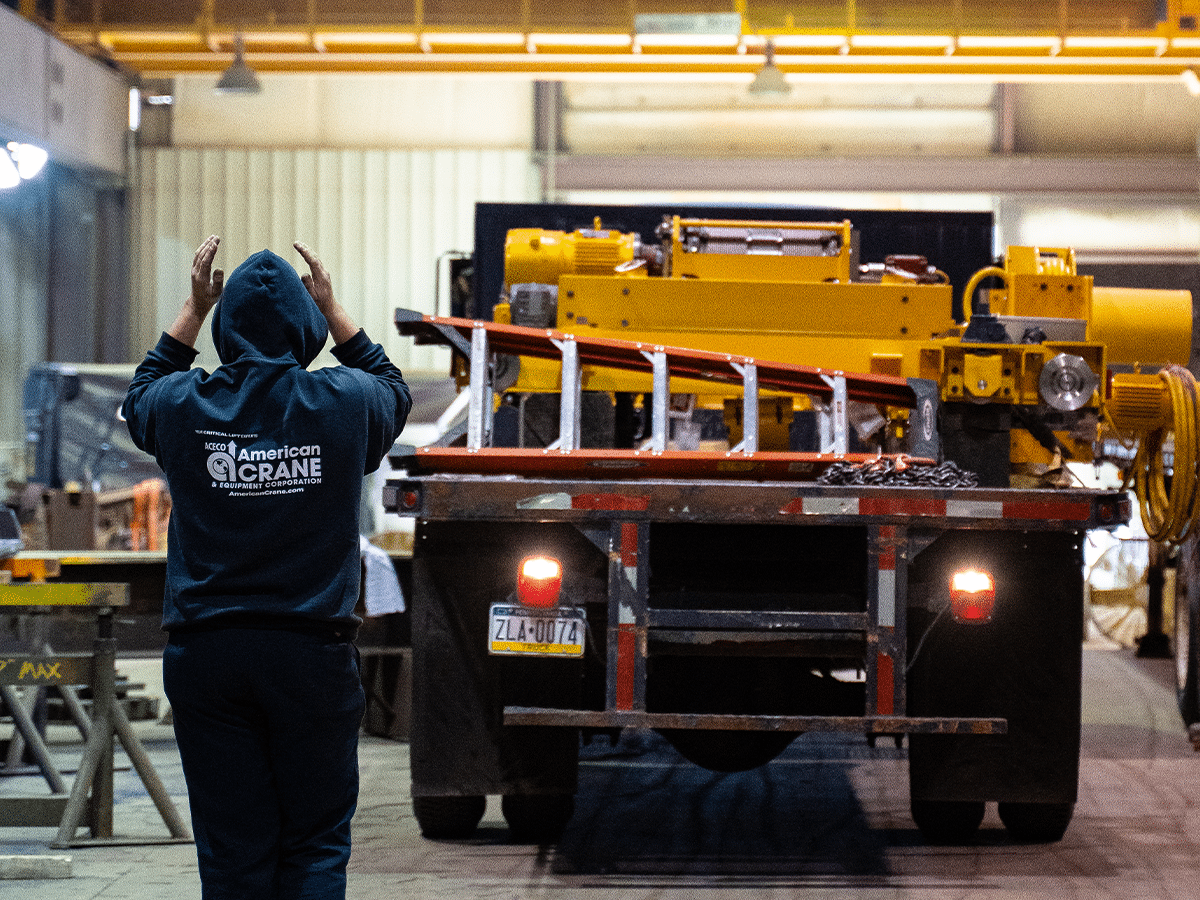

Our finishing mill cranes are custom-designed to meet the specific requirements of your facility. We take pride in delivering high-quality solutions that surpass your expectations. Our cranes are constructed with the latest technology and innovative features to ensure maximum performance and reliability. Choosing American Crane means investing in a superior product that will provide long-term value.

High-Performance Aluminum Mill Cranes

Cranes crafted specifically for aluminum mills are typically rated Class D, E, or F, and are designed to accommodate heavy-duty, heavy-load carrying. These cranes offer superior performance and reduced mill maintenance, featuring deep hardened wheels, continuous-duty motors, high-performance Class H insulation, base-mounted gear reducers horizontally split with helical gearing, self-aligning spherical roller wheel bearings, heavy-duty sheaves, motions equipped with variable speed drives, optimized bridge, hoist, and trolley gearing, bridge speeds up to 400 FPM, and rope drums with hardened grooves.

Mastering Steel Mill Operations

High-Performance Steel Mill Cranes

The steel industry demands top-quality, reliable material handling equipment, with cranes used in steel mills required to handle extremely heavy loads and endure harsh environments. To meet these specific industry needs, a wide range of specialized steel mill cranes are available, including:

- Slab steel mill cranes — Designed to endure high temperatures and harsh environments, ensuring safe, reliable slab handling with uncompromising smoothness and safety assurance.

- Scrap steel mill cranes — Engineered for heavy scrap management in steel manufacturing, offering smooth, safe, and reliable operation in high-temperature and harsh conditions.

- Tundish cranes — Specifically designed for tundish handling and material management in steel processing, providing adaptability, reliability, and superior safety assurance.

- Coil and plate handling cranes — Crafted for both indoor and outdoor facilities, available in a wide range of tonnage capacities and sizes, engineered to span 10.5 to 31.5 meters and manage 5 to 550 tons.

- Billet steel mill cranes — Designed for lifting the most difficult steel loads, such as molten metal, steel coils, steel byproducts, and mixed materials. These cranes can manage high or drastically fluctuating temperatures and offer versatile and reliable handling options.

- Ladle cranes — These cranes offer smooth operation and sophisticated safety features for ladle handling of liquid loads in steel manufacturing.

Pioneering Metal Finishing Solutions

Finishing Mill Solutions From American Crane

With over 40 years of experience building cranes and hoist solutions, American Crane is the industry leader in providing specialized metal finishing and processing mills solutions. We offer material handling equipment, hoist systems, and cranes for various industries, including marble and granite processing, shipping, waste management, and energy and nuclear production. Our solutions range from ¼-ton hoists to equipment with 300 tons of overhead lifting capacity. We guarantee that our cranes and hoists exceed CMAA duty cycle requirements for service classifications A through F and offer a comprehensive in-house quality assurance program for every unit. We thoroughly test each product before shipment. Contact our team today to learn more about our custom steel-industry tools, mill-equipped cranes, and lifting solutions.