Enhancing Industrial Process Efficiency

Coke Handling Cranes & Hoist Systems

Coke-handling cranes are used in the steelmaking industry to handle coke, a fuel used to produce iron. These cranes are designed to withstand harsh environments and extreme temperatures. They are also equipped with advanced safety features that ensure the safety of workers and prevent damage to equipment. Using coke-handling cranes can significantly increase the efficiency and productivity of steel plants.

These cranes can handle large quantities of coke in a short amount of time, reducing the need for manual labor. With the help of specialized software and automation, coke-handling cranes can perform complex tasks with precision and accuracy. Overall, coke-handling cranes are an essential piece of equipment in the steelmaking industry and play a crucial role in ensuring iron’s safe and efficient production.

Specialized Automation for Coker Crane Handling

Coker crane handling is best performed using advanced automation technology. It can be operated either fully or semi-automatically, depending on the task at hand. Full automation ensures efficient operation and minimal human intervention, while semi-automation provides greater control and flexibility, with manual intervention possible for unanticipated situations. Regardless of the mode of operation, safety is always a top priority, and all coker crane handling systems are designed to meet the highest safety standards.

- Full automation: These systems operate without humans in the interface and can be run from a remote operating station, which is ideal for dangerous environments. An operator is still required to oversee the system and assist it with certain tasks that are best suited for human operation.

- Semi-automation: One level above manual control, semi-automation occurs when the operator activates certain tasks in the system.

Empowering Diverse Industries with Crane Technology

Crane Automation’s Role in Key Industrial Sectors

Many industries operate in challenging environments and rely on crane automation to perform their work safely. The technology of coke handling cranes and hoist systems is a necessary part of heavy lifting in the following industries:

- Aviation: In this industry, heavy objects need to be moved along assembly lines throughout ongoing construction projects. Due to their accuracy and reliability, overhead cranes are the best tools to use especially when moving expensive components.

- Concrete manufacturing: Overhead cranes are highly efficient at moving large and heavy concrete premix and precast. Typically, gantry cranes are used outdoors while bridge cranes operate inside the factory.

- Metal manufacturing: Extreme temperatures and heavy materials require specialized equipment to ensure worker safety. The metal manufacturing industry uses automatic cranes to handle molten metal with specialized attachments.

- Power plants: Power plants must remain functional at all times, so they rely heavily on automated crane technology to quickly fix any problem that arises. Overhead cranes also save vital workspace and deliver the dependable performance required by this demanding industry.

- Shipbuilding: Because ships are large, heavy, and complexly shaped, the shipbuilding industry relies on the freedom of movement and stability that overhead cranes—especially gantry cranes—can provide.

- Transportation and automotive: Overhead cranes unload large containers from ships, boosting the speed and efficiency of the transportation industry. In the automotive space, overhead cranes increase efficiency on assembly lines by moving materials between stations.

Enhancing Industrial Safety and Efficiency

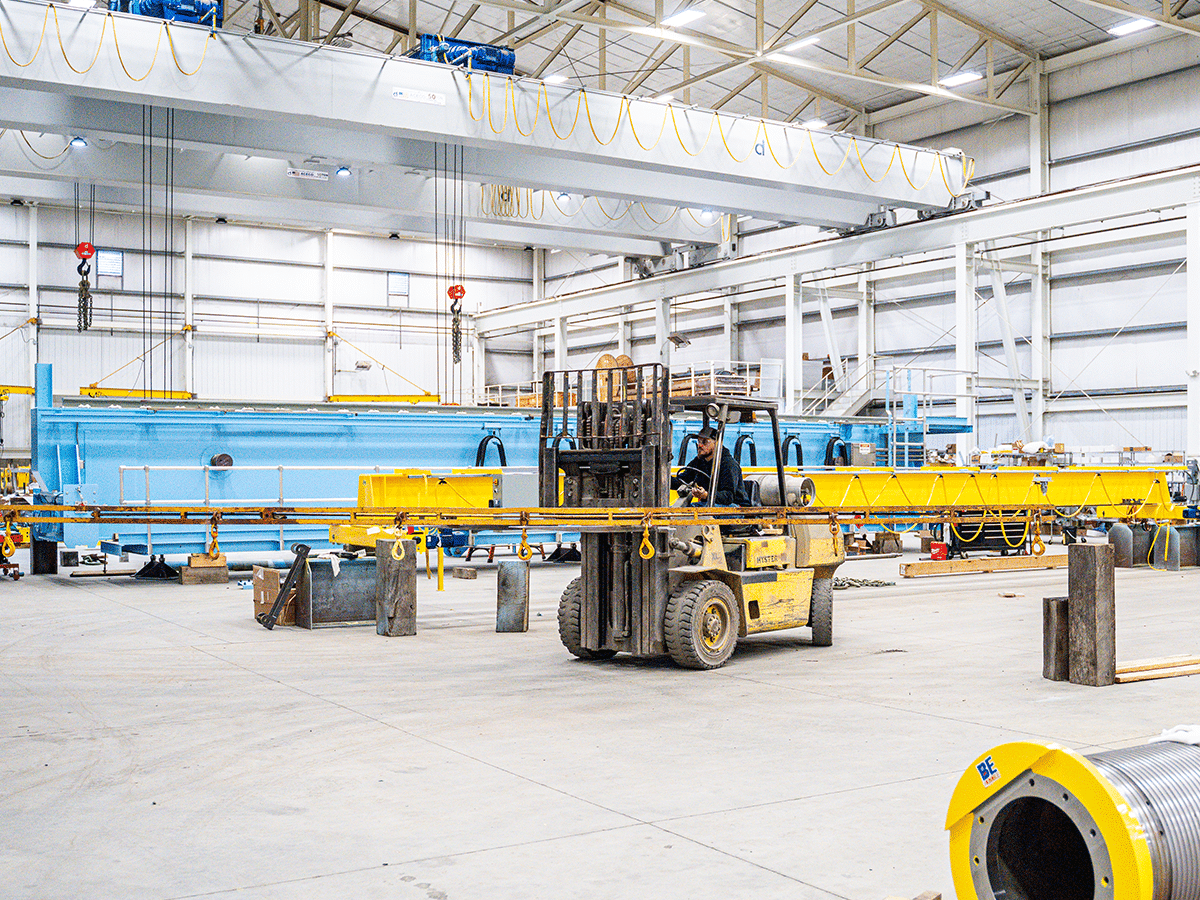

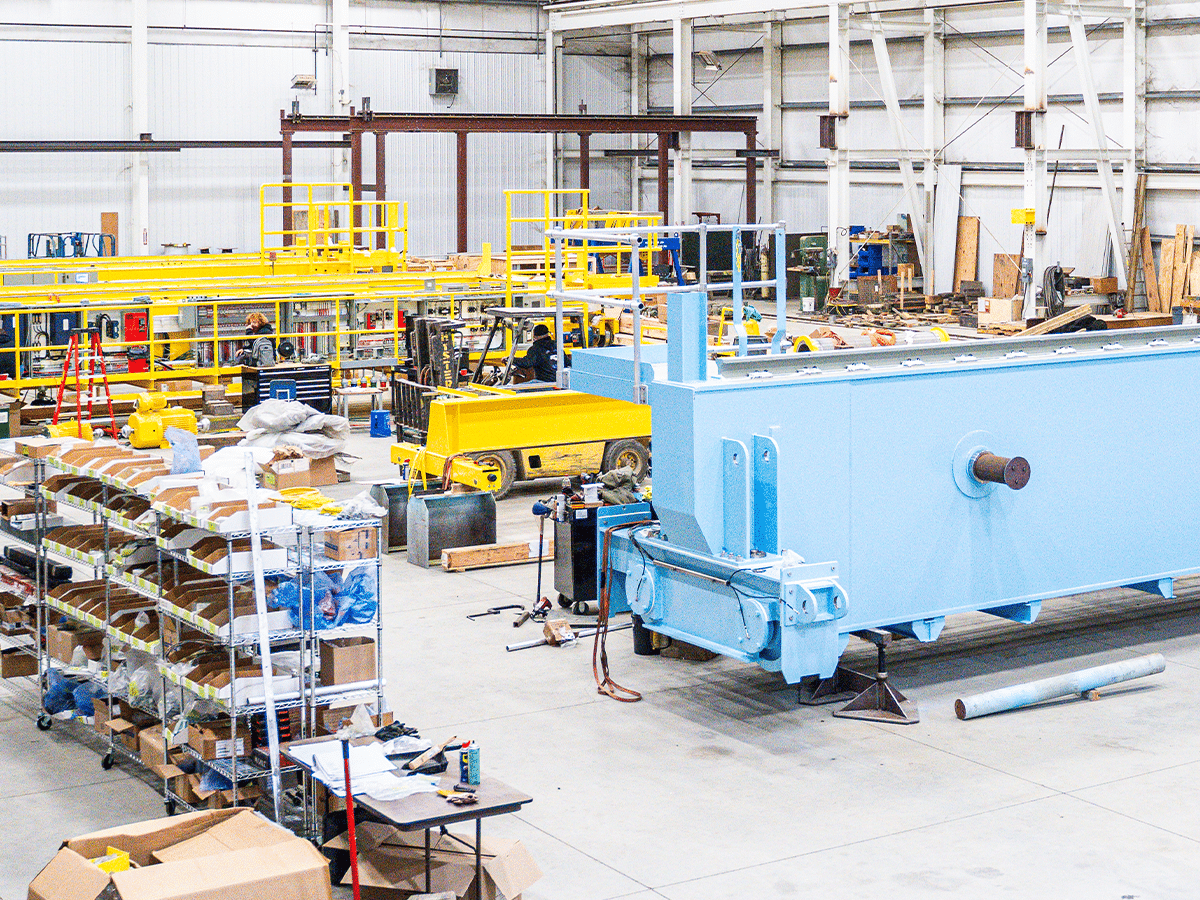

Customized Coke Handling Solutions by American Crane

Coke-handling cranes and hoist systems make working in dangerous environments easier. Automated cranes increase efficiency in many industries—transportation, aviation, and concrete manufacturing—and can operate safely.

American Crane has over 40 years of experience delivering industry-leading lifting solutions. We design coker cranes that provide exceptional safety and longevity while exceeding industry guidelines. Each unit we produce is supported by our comprehensive quality assurance program and is shipped fully assembled. To learn more about our custom services and lifting solutions, contact us today or request a quote.