Jib Cranes: Your Flexible, Safe, & Efficient Solution for Lifting

Leave a Comment

If you’re navigating the complex world of industrial lifting and material handling, you’ve probably found yourself in a situation where traditional cranes just don’t cut it. Enter jib cranes, the underdog that’s quickly becoming a cornerstone in various industries. Whether it’s assembly lines in manufacturing or heavy-duty jobs in construction, a jib crane’s adaptability and efficiency can’t be overstated.

What Makes Jib Cranes Stand Out?

Jib cranes offer a unique blend of flexibility and power, ideal for tasks requiring a high degree of precision. These cranes are commonly wall-mounted or freestanding, giving you the liberty to choose an installation that suits your operational needs. Designed with steel components, their robust construction ensures durability while adding a layer of safety.

Versatility in Operations

No one likes to be confined, especially when there are tasks to complete and deadlines to meet. Jib cranes have an impressive span range, allowing you to cover a significant area of your workspace without the need for multiple hoists. This is incredibly beneficial in manufacturing settings where assembly lines or mobile workstations are used.

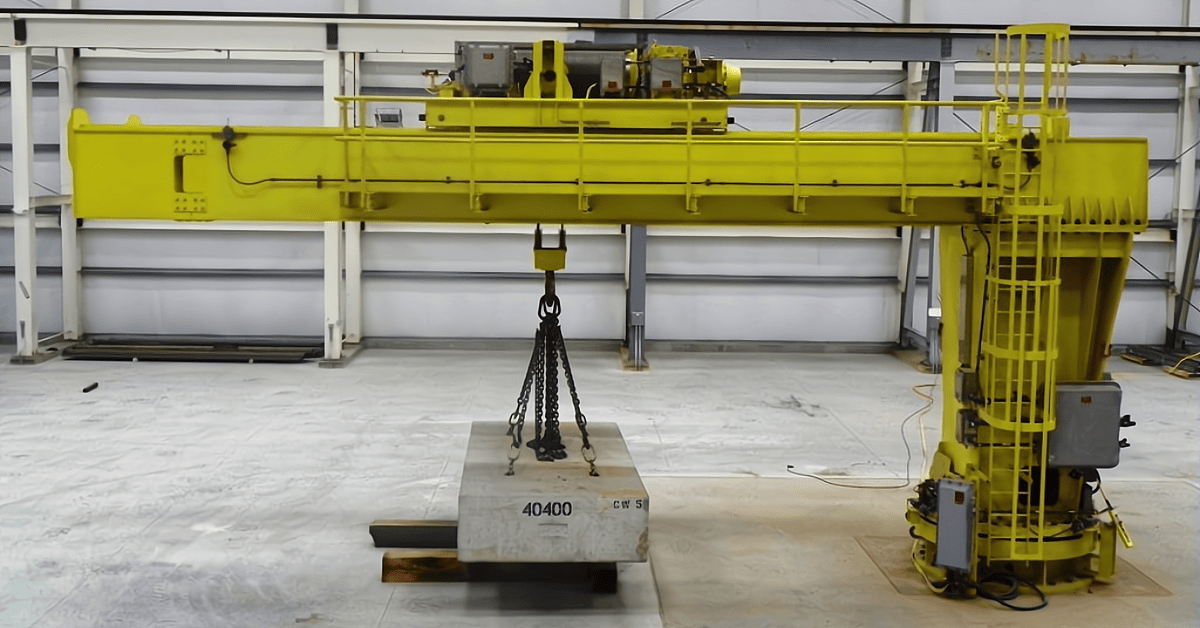

Lifting Capacity: More Than Just Numbers

When it comes to handling heavy materials, lifting capacity is not something to be overlooked. Jib cranes offer a range of options in this department. Whether you need to lift a small engine component or a bulk load of steel, there’s a jib crane designed to handle the weight. By tailoring the crane’s capacity to your specific needs, you avoid overcommitting resources, thus saving time and money.

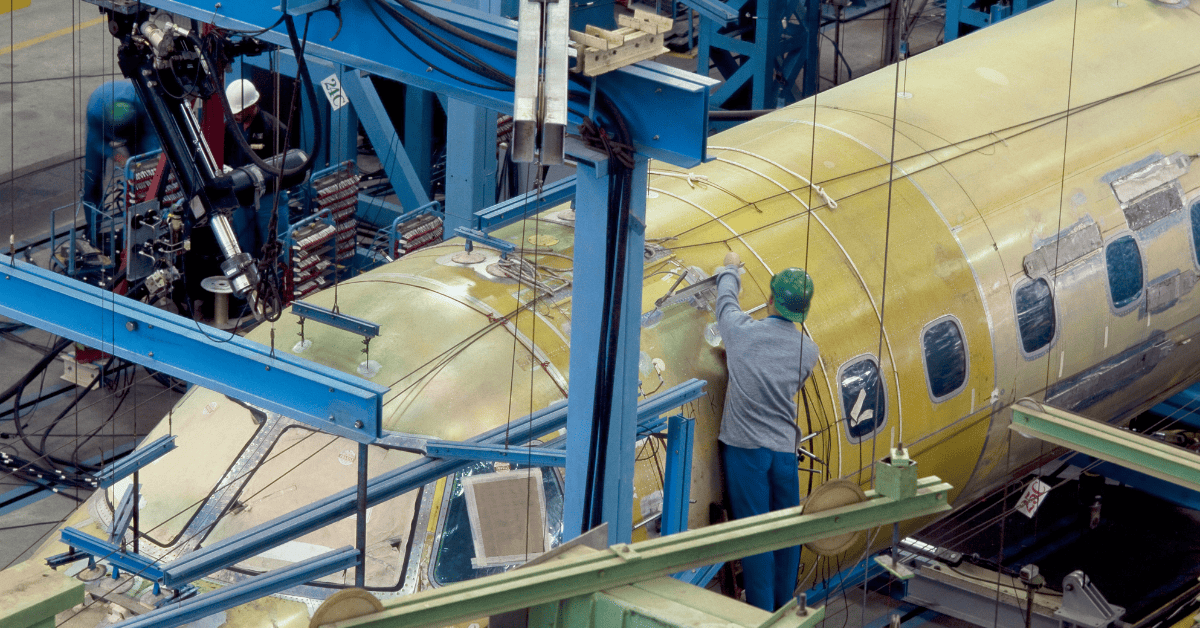

The Choice of Industries

Given their versatility, it’s no wonder that jib cranes have made their mark across various industrial landscapes. The construction industry often employs these cranes for handling a wide range of materials. Meanwhile, manufacturing plants benefit from their ability to move along assembly lines with minimal disruption.

Spanning the Gap with Overhead Options

If your workspace is more vertical than horizontal, overhead jib cranes could be your answer. They’re perfect for lifting objects to significant heights without sacrificing floor space. This can be a game-changer in workshops where square footage is at a premium but lifting needs are high.

Keep Things Moving with Mobile Jib Cranes

Let’s face it: In today’s fast-paced industrial environment, mobility is key. Mobile jib cranes provide the perfect solution for on-the-go tasks. They’re particularly useful in shipping yards and outdoor construction sites where moving materials from point A to point B is a daily routine.

Safety and Ease in Material Handling

Now, we can’t talk about jib cranes without addressing one of the most critical aspects: safety. In industrial environments, mishaps can be costly—not just in terms of money but also human lives. Jib cranes come equipped with advanced safety features that are designed to minimize risks during operations. Advanced hoists, durable steel construction, and a range of safety options contribute to making your work environment as secure as possible. Plus, because these cranes are so easy to operate, training your staff becomes a more straightforward task.

Customization for Your Unique Needs

Every industrial operation is unique, and your material handling solutions should be too. Jib cranes offer unparalleled levels of customization. Whether you’re looking for wall-mounted options for limited space or a freestanding unit that can be moved around your facility, there’s a fit for you. Also, the customization doesn’t stop at the mounting; various hoists can be attached to suit the materials you’re working with. From metals to chemicals and everything in between, you can tailor your crane system to meet your specific handling requirements.

Maintenance: Simpler than You Think

Ah, maintenance—no one likes to talk about it, but it’s crucial for any industrial equipment. One of the selling points for jib cranes is their ease of maintenance. Because of their straightforward design and robust construction, these cranes require less upkeep compared to other types of lifting equipment. This translates into fewer work stoppages and more efficient use of your time and resources.

Go Beyond the Standard with Special Features

If you’re looking to go the extra mile, some jib cranes come with additional features like extended spans and higher lifting capacities. These aren’t your run-of-the-mill cranes; they’re specially designed to cater to more demanding industrial tasks. Such features make these cranes ideal for large-scale projects or specialized applications that require more than what standard cranes can offer.

Your Partner in Efficiency and Safety

At this point, it’s clear that jib cranes offer a blend of efficiency, customization, and safety that’s hard to beat. So why settle for less? If you’re aiming to optimize your material handling processes, it might be high time to take a closer look at what jib cranes can do for you. Still, have questions or are ready to make a choice? Don’t hesitate to get in touch with American Crane. We’re here to guide you through your options and help you make the best decision for your operation.