Jib Cranes: Your Flexible, Safe, & Efficient Solution for Lifting

Leave a Comment

If you’re navigating the complex world of industrial lifting and material handling, you’ve probably found yourself in a situation where traditional cranes just don’t cut it. Enter jib cranes, the underdog that’s quickly becoming a cornerstone in various industries. Whether it’s assembly lines in manufacturing or heavy-duty jobs in construction, a jib crane’s adaptability and efficiency can’t be overstated.

What Makes Jib Cranes Stand Out?

Jib cranes offer a unique blend of flexibility and power, ideal for tasks requiring a high degree of precision. These cranes are commonly wall-mounted or freestanding, giving you the liberty to choose an installation that suits your operational needs. Designed with steel components, their robust construction ensures durability while adding a layer of safety.

Versatility in Operations

No one likes to be confined, especially when there are tasks to complete and deadlines to meet. Jib cranes have an impressive span range, allowing you to cover a significant area of your workspace without the need for multiple hoists. This is incredibly beneficial in manufacturing settings where assembly lines or mobile workstations are used.

Lifting Capacity: More Than Just Numbers

When it comes to handling heavy materials, lifting capacity is not something to be overlooked. Jib cranes offer a range of options in this department. Whether you need to lift a small engine component or a bulk load of steel, there’s a jib crane designed to handle the weight. By tailoring the crane’s capacity to your specific needs, you avoid overcommitting resources, thus saving time and money.

The Choice of Industries

Given their versatility, it’s no wonder that jib cranes have made their mark across various industrial landscapes. The construction industry often employs these cranes for handling a wide range of materials. Meanwhile, manufacturing plants benefit from their ability to move along assembly lines with minimal disruption.

Spanning the Gap with Overhead Options

If your workspace is more vertical than horizontal, overhead jib cranes could be your answer. They’re perfect for lifting objects to significant heights without sacrificing floor space. This can be a game-changer in workshops where square footage is at a premium but lifting needs are high.

Keep Things Moving with Mobile Jib Cranes

Let’s face it: In today’s fast-paced industrial environment, mobility is key. Mobile jib cranes provide the perfect solution for on-the-go tasks. They’re particularly useful in shipping yards and outdoor construction sites where moving materials from point A to point B is a daily routine.

Safety and Ease in Material Handling

Now, we can’t talk about jib cranes without addressing one of the most critical aspects: safety. In industrial environments, mishaps can be costly—not just in terms of money but also human lives. Jib cranes come equipped with advanced safety features that are designed to minimize risks during operations. Advanced hoists, durable steel construction, and a range of safety options contribute to making your work environment as secure as possible. Plus, because these cranes are so easy to operate, training your staff becomes a more straightforward task.

Customization for Your Unique Needs

Every industrial operation is unique, and your material handling solutions should be too. Jib cranes offer unparalleled levels of customization. Whether you’re looking for wall-mounted options for limited space or a freestanding unit that can be moved around your facility, there’s a fit for you. Also, the customization doesn’t stop at the mounting; various hoists can be attached to suit the materials you’re working with. From metals to chemicals and everything in between, you can tailor your crane system to meet your specific handling requirements.

Maintenance: Simpler than You Think

Ah, maintenance—no one likes to talk about it, but it’s crucial for any industrial equipment. One of the selling points for jib cranes is their ease of maintenance. Because of their straightforward design and robust construction, these cranes require less upkeep compared to other types of lifting equipment. This translates into fewer work stoppages and more efficient use of your time and resources.

Go Beyond the Standard with Special Features

If you’re looking to go the extra mile, some jib cranes come with additional features like extended spans and higher lifting capacities. These aren’t your run-of-the-mill cranes; they’re specially designed to cater to more demanding industrial tasks. Such features make these cranes ideal for large-scale projects or specialized applications that require more than what standard cranes can offer.

Your Partner in Efficiency and Safety

At this point, it’s clear that jib cranes offer a blend of efficiency, customization, and safety that’s hard to beat. So why settle for less? If you’re aiming to optimize your material handling processes, it might be high time to take a closer look at what jib cranes can do for you. Still, have questions or are ready to make a choice? Don’t hesitate to get in touch with American Crane. We’re here to guide you through your options and help you make the best decision for your operation.

Custom Crane Manufacturing: Lifting Industries One Lift at a Time

Leave a Comment

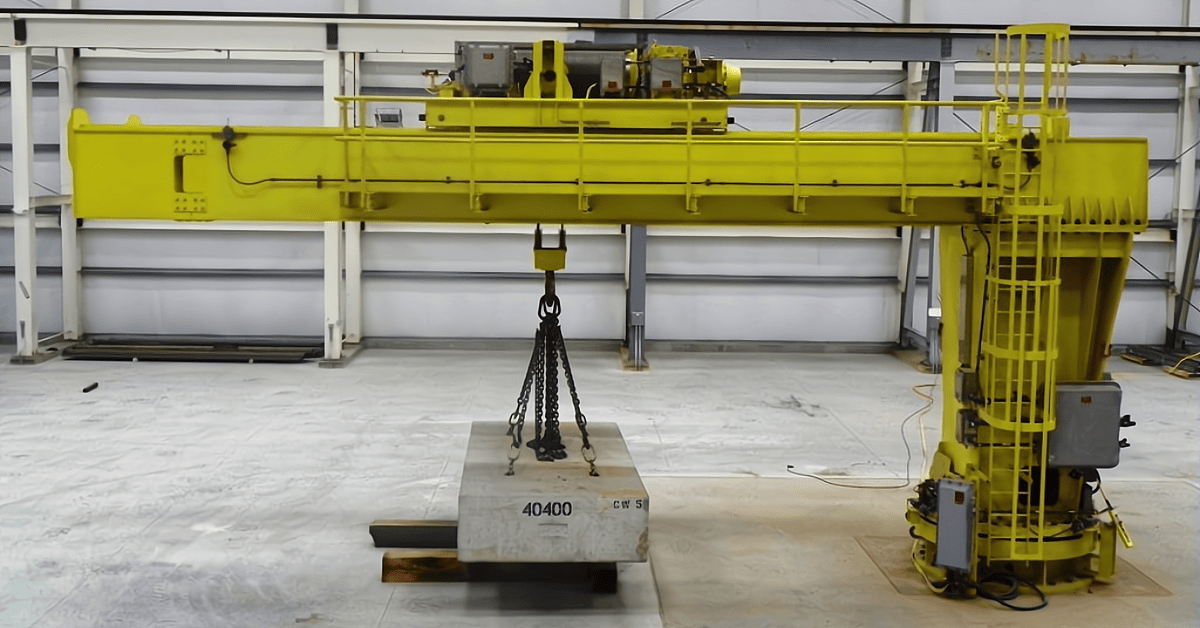

When you’re in an industry that relies on heavy lifting, you know the importance of dependable equipment. That’s where custom crane manufacturing comes into play. Sure, there are off-the-shelf options. But custom-built cranes? They’re the powerhouses that elevate your operations to the next level.

Why Go Custom?

In any industrial application, one size rarely fits all. You need a crane that’s tailored to your specific needs. Whether you’re in bridge construction, engineering, or any other sector that demands precision lifting, a custom crane offers a service that standard cranes just can’t match.

Decades Of Experience

With decades of experience under our belt, we’ve seen firsthand how the right crane can make or break a project. Custom crane manufacturing allows for the design and fabrication of cranes specifically suited to your application. This can range from overhead cranes for massive warehouses to jib cranes for more compact spaces.

Parts and Components That Last

Now, let’s talk materials. When you opt for custom, you get to choose the parts that go into your crane, and this plays a critical role in durability. The longevity of lifting devices and other integral components can be fine-tuned to withstand the test of time, weather, and rigorous use.

Engineered to Your Needs

The hoist, for instance, can be engineered with your specific lifting requirements in mind. Need a heavy-duty, weather-resistant option? Consider it done. The beauty of custom manufacturing is that the materials and parts can be selected based on your unique demands.

Engineering Excellence and Expertise

When it comes to the actual design and engineering, the sky’s the limit. Skilled engineers work on your project, bringing their wealth of knowledge to the table. They consider every detail, from systems for easy maneuverability to the ideal resources for load testing.

Get More Than Just a Crane

But a crane is more than just metal and mechanics. It’s also about the experience and service that come along with it. Post-sales support, for example, should never be underestimated. Whether you need on-the-spot repairs or regular maintenance, a custom crane manufacturer can often offer a more comprehensive and responsive service package than a one-size-fits-all provider.

Customized to Your Needs

The custom approach extends even to the smaller, yet vital, elements like crane accessories and devices. Think hooks, slings, and load indicators—all can be customized to harmonize with your crane’s primary function.

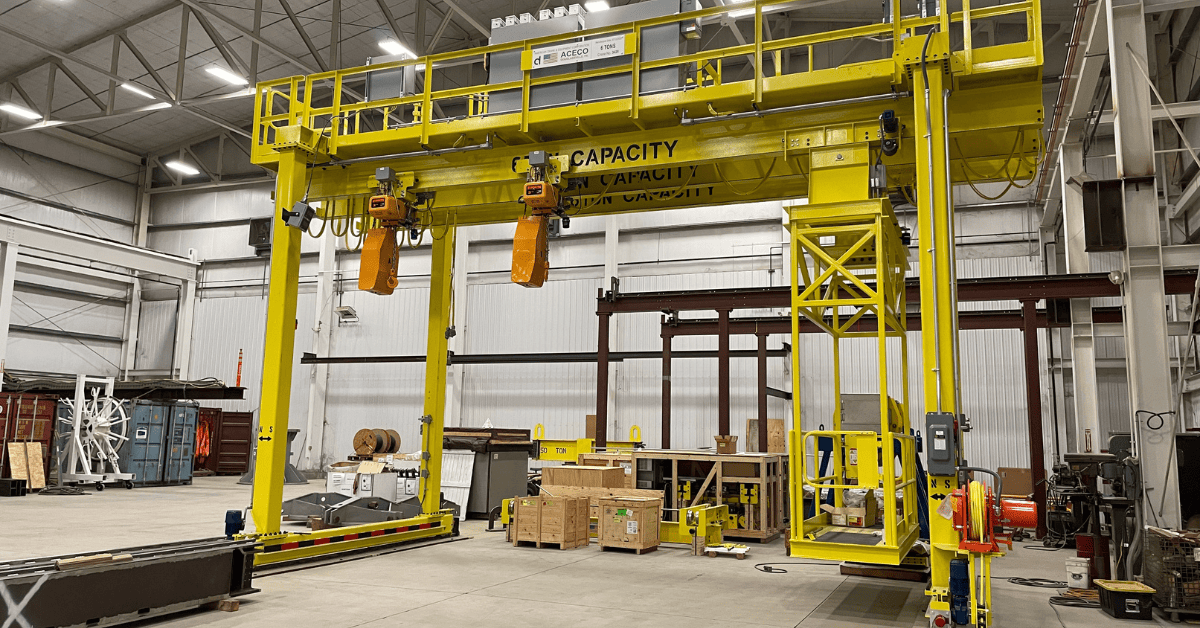

The Nuts and Bolts of Customization

When we dive into the specifics of customization, it’s not just about size and lifting capacity. Even the bridge of the crane can be designed to maximize efficiency in your workspace. From the electronic systems that power the crane to the braking systems that ensure safety, every detail is accounted for. We bring together the best in engineering and manufacturing to create a crane that’s uniquely yours.

A Network of Support

Buying a custom crane is an investment, and like any good investment, you want it to be well-supported. That’s where our extensive network of resources and services comes into play. From initial consultation to the actual operation of your crane, you’re never alone. We offer ongoing maintenance and inspection services, ensuring your equipment is always up to par.

Safety Above All Else

Of course, we can’t talk about cranes without addressing safety. Custom crane manufacturing is always carried out with strict adherence to safety guidelines and regulations. Because these cranes are designed for your specific application, they are inherently safer. Our engineers assess your worksite, the materials you’re lifting, and even the climate you’re operating in to ensure that the crane meets or exceeds all safety standards.

Why Custom Crane Manufacturing is a Game-Changer

We’ve touched on several important points—from the superiority of custom design to the unparalleled customer service that accompanies it. But the real game-changer is the impact on your bottom line. Time saved is money earned, and custom cranes significantly reduce the time taken for numerous tasks. They are efficient, reliable, and optimized for your specific industrial application, making them an invaluable asset to your operation.

Parts Availability and Upgrades

No machine lasts forever without a little TLC. The good news is that custom crane manufacturing usually means easy access to parts and even potential upgrades. Need to retrofit your crane with new features down the line? That’s often easier with a custom-built machine.

Custom Crane Manufacturing at American Crane

Custom crane manufacturing offers a host of advantages, from precise engineering and high-quality materials to unparalleled customer service. If you’re looking to make the leap to custom, reach out to American Crane today!

Aerospace Overhead Cranes: A Match Made for the Skies

Leave a Comment

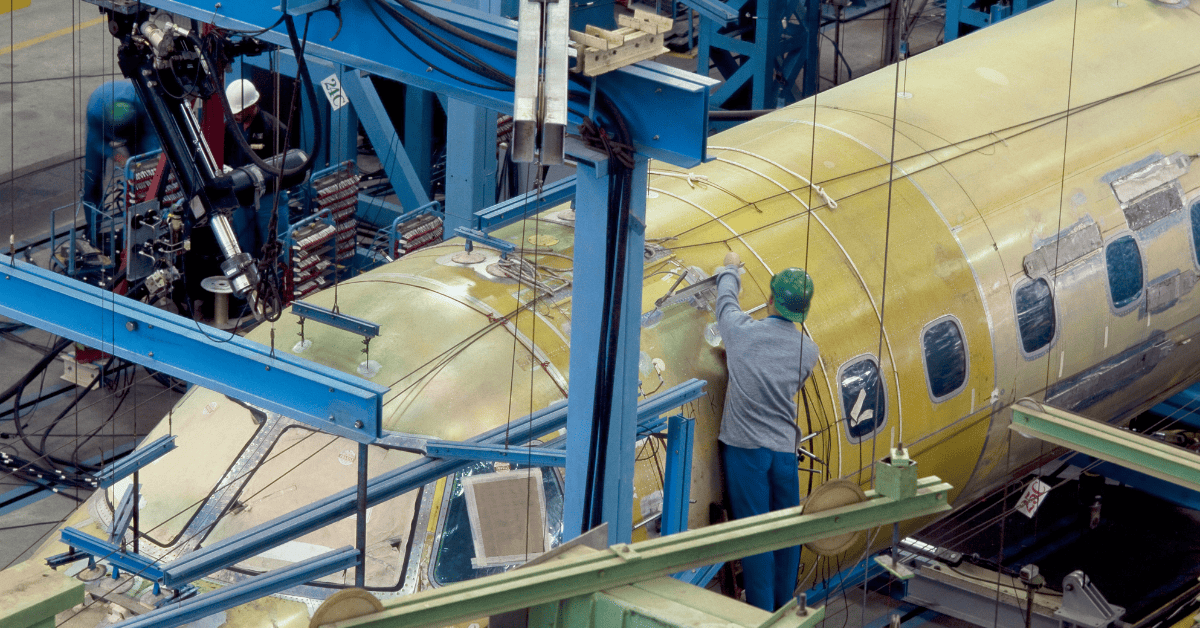

So you’re in the aerospace business, where precision, reliability, and durability are not just buzzwords but daily necessities. Let’s face it, when you’re manufacturing or maintaining anything that’s designed to take to the skies, there’s no room for error. Whether it’s assembling massive jet engines or handling sensitive composite materials, you need equipment that meets your lofty standards. That’s where aerospace overhead cranes come into play.

Why Overhead Cranes Are Crucial for Aerospace

The aerospace industry is unique—planes aren’t cars, and rockets aren’t trains. Standard material handling equipment just doesn’t cut it. Enter overhead cranes. These are not your average cranes; these are specialized systems designed for the intricate and sensitive tasks that aerospace demands. Picture this: You have a colossal jet engine that needs to be moved from one end of the warehouse to another. Sure, you could try using a forklift, but do you really want to gamble with a multi-million-dollar piece of machinery?

Material Handling You’ve Never Seen Before

An overhead crane system can easily, safely, and efficiently handle your most valuable aviation assets. We’re talking about bridge cranes that span your workspace, fitted with hoists specifically engineered for precision lifts. Say goodbye to the awkward maneuvers that come with standard material handling equipment. Overhead cranes can move smoothly along their track, carrying everything from wings to engines as if they were feather-light.

Built for Endurance and Precision

Manufacturing in aerospace means dealing with a wide range of materials and components. You’re often managing delicate composite materials one minute and robust metal alloys the next. Aerospace overhead cranes can be customized to meet the unique needs of each manufacturing stage. Hoists can be outfitted with special grips and lifts to handle the most sensitive materials, ensuring that they reach their destination in perfect condition.

No Job Too Big or Small

In aerospace, size matters. You may be assembling small drones one day and working on jumbo jets the next. Versatility is a must. With modular designs and customizable features, aerospace overhead cranes are made to adapt to your evolving needs. You can modify the track, adjust the jib, and even switch out the hoists to meet the specific requirements of any project.

Safety and Maintenance, Front and Center

Let’s not forget about the importance of regular inspection and maintenance. Aerospace overhead cranes are built for longevity, but they’re not invincible. Regular check-ups and timely maintenance ensure that your material handling systems are always in tip-top shape. After all, a faulty crane could be more than just a productivity bottleneck—it could be a safety hazard.

The Right Crane for the Right Job: Customization is Key

Choosing an aerospace overhead crane isn’t a one-size-fits-all situation. Every aviation project has its own set of challenges and requirements. Maybe you’re dealing with the tight constraints of a small workshop, or perhaps you have a sprawling manufacturing floor that’s bustling with different activities. Either way, customization is your best friend. Most overhead crane systems offer a range of options, from the type of hoist to the length of the bridge and track. This adaptability ensures you’ll have a material handling solution that fits your workspace like a glove.

Future-Proofing Your Operations

Technology is constantly evolving, especially in an industry as dynamic as aerospace. That’s why it’s essential to invest in overhead cranes that are upgradable. Whether you’re anticipating changes in material types, weight capacities, or even automation features, a modular crane system can grow alongside your business. This way, you’re not just solving today’s challenges but preparing for tomorrow’s opportunities as well.

Reducing Downtime, Maximizing Productivity

In aerospace manufacturing and maintenance, time is money. Delays in material handling can have a cascading effect, disrupting tightly coordinated schedules. Aerospace overhead cranes are designed for speed and efficiency. Their intuitive controls and high-speed hoists enable your team to move materials swiftly, cutting down on downtime and boosting overall productivity.

Why Choose American Crane?

You might be wondering, with all the options out there, why go with American Crane? Well, we bring decades of expertise and a solid track record to the table. We understand the aerospace sector’s complexities and nuances and commit to delivering robust, reliable, and tailored solutions that meet your specific needs. With American Crane, you’re not just getting a piece of equipment; you’re entering into a long-term partnership. We stand by our products and offer ongoing support, from the initial consultation to routine maintenance and inspections. Our aim is to make sure your material handling systems are always functioning at their best, so you can focus on reaching for the stars.

Embracing Excellence: The Core Value of Practicing Follow Through at ACECO

Leave a Comment

In a world brimming with promises and intentions, there’s a distinctive trait that sets exceptional companies apart – their commitment to Practice Follow Through. At American Crane & Equipment Corporation (ACECO), this core value is more than a mere slogan; it’s a way of life that defines the very essence of the company’s operations and interactions. In this blog, we delve into the significance of Practicing Follow-Through and how ACECO embodies this value to create lasting impacts and build trust.

The Essence of Practicing Follow-Through:

At its core, Practicing Follow Through means translating words into actions consistently and reliably. It’s about demonstrating dedication and integrity by delivering on promises, even when no one is watching. As the saying goes, “You are what you do, not what you say you do.” This principle resonates deeply at ACECO, where every commitment made is a vow etched in stone, backed by an unwavering dedication to execution.

Building Trust and Credibility:

In an era of rapid communication and information exchange, building trust has never been more crucial. ACECO understands that trust is not simply gained through words; it’s earned through consistent actions. When customers, partners, and employees witness the Practicing of Follow Through in action, a strong foundation of trust is laid. ACECO’s reputation for delivering results fosters credibility and cultivates long-lasting relationships.

Delivering Excellence in Every Endeavor:

ACECO’s commitment to Practice Follow-Through is evident in every project, from intricate engineering feats to streamlined logistical operations. Its value becomes especially pronounced when challenges arise. Instead of shying away from difficulties, ACECO rises to the occasion, standing behind our commitments and finding innovative solutions to ensure successful project completion.

Empowering Employees:

This practice isn’t limited to external interactions; it permeates the internal culture of ACECO as well. The company empowers its employees to take ownership of their responsibilities and deliver results. When employees witness their leaders embodying the Practice Follow Through core value, it inspires them to follow suit, creating a culture of accountability and excellence.

Driving Continuous Improvement:

At ACECO, resting on laurels is not an option. We are in the business of continually improving and surpassing expectations. We view each project as an opportunity to learn, adapt, and enhance our processes. By consistently evaluating performance and seeking ways to optimize outcomes, ACECO demonstrates a commitment to Practicing Follow-Through at every stage of its operations.

Practicing Follow-Through is more than a core value at American Crane & Equipment Corporation; it’s the heartbeat that propels the company’s success. Through unwavering dedication to turning words into actions, ACECO has not only earned the trust and respect of its customers but has also cultivated a culture of excellence that permeates every facet of its operations.

To learn more about Our Vision, Mission, & Values, visit https://www.americancrane.com/mission-values