A hoist helps to raise and lower heavy loads and is sometimes used to transport objects from one location to another. There are many types of hoists that may be operated manually, pneumatically, or electronically. This mechanical device most often features one or multiple fixed pulleys, a moving pulley with a hook or other component for attaching loads, and a braided rope between them. As a leading manufacturer of hoists, American Crane can help you decide on the best crane hoist for your project’s needs.

A hoist helps to raise and lower heavy loads and is sometimes used to transport objects from one location to another. There are many types of hoists that may be operated manually, pneumatically, or electronically. This mechanical device most often features one or multiple fixed pulleys, a moving pulley with a hook or other component for attaching loads, and a braided rope between them. As a leading manufacturer of hoists, American Crane can help you decide on the best crane hoist for your project’s needs.

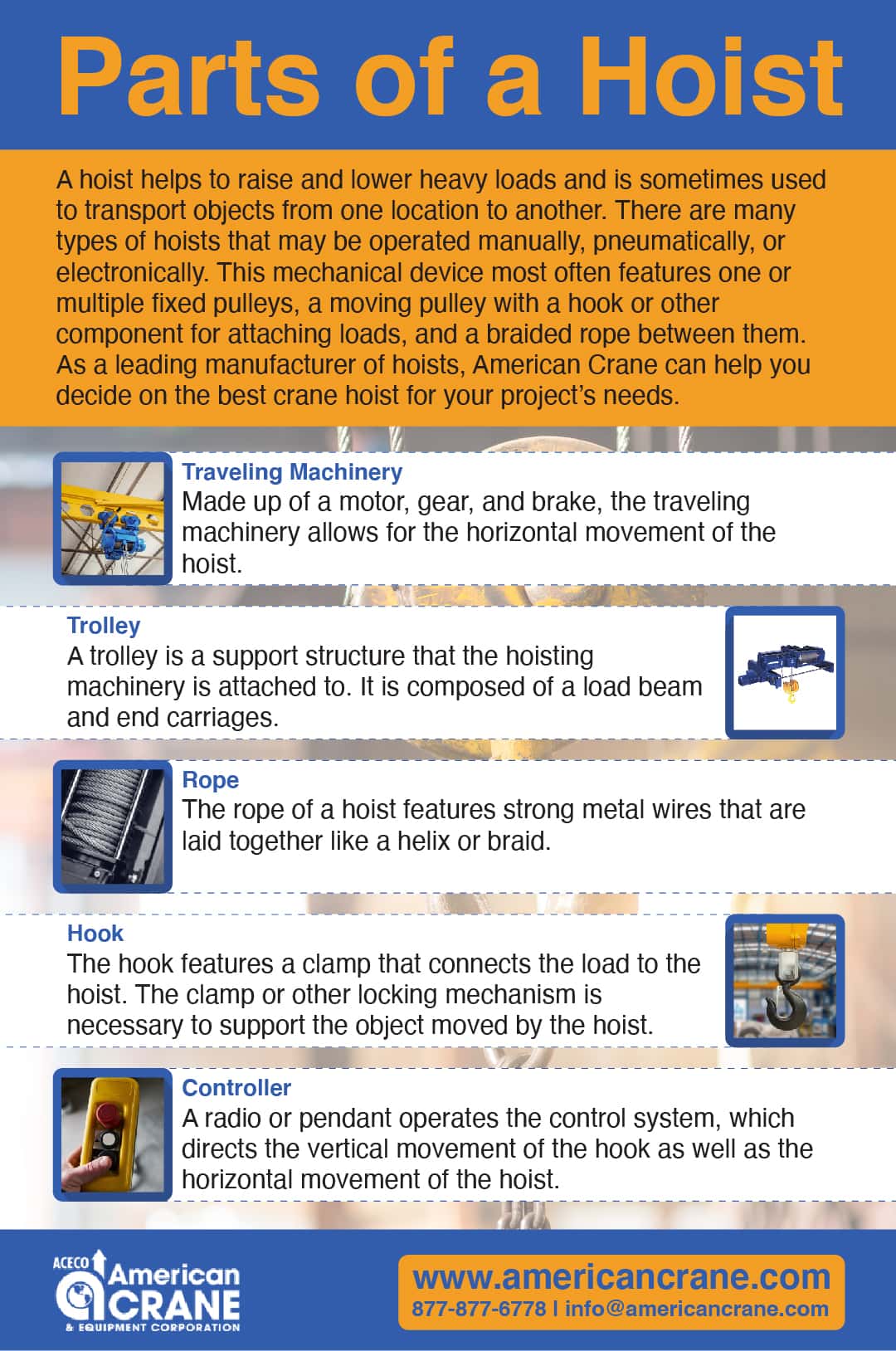

Parts of a Hoist

There are many components that make up a hoist, including:

● Traveling Machinery. Made up of a motor, gear, and brake, the traveling machinery allows for the horizontal movement of the hoist.

● Trolley. A trolley is a support structure that the hoisting machinery is attached to. It is composed of a load beam and end carriages.

● Rope. The rope of a hoist features strong metal wires that are laid together like a helix or braid.

● Hook. The hook features a clamp that connects the load to the hoist. The clamp or other locking mechanism is necessary to support the object moved by the hoist.

● Controller. A radio or pendant operates the control system, which directs the vertical movement of the hook as well as the horizontal movement of the hoist.

How a Hoist Works

Operating a hoist includes knowing the weight restrictions and requirements as well as built-in safety features. The operator may set operating limits of a hoist, which limit movements under certain circumstances. A hoist also comes with safety features that prevent overloading a lift, limit travelling movement, or prevent all movements with an emergency stop button.

Operating a hoist includes knowing the weight restrictions and requirements as well as built-in safety features. The operator may set operating limits of a hoist, which limit movements under certain circumstances. A hoist also comes with safety features that prevent overloading a lift, limit travelling movement, or prevent all movements with an emergency stop button.

Once all regulations and requirements are set, the operator uses the controller to activate the relevant button or joystick to move the hook vertically. The signals given by the operator, along with any safety devices or sensors, control the break and motor. When the hoist receives the signal, power is supplied to the motor, releasing the break. The motor drives the hoisting gear, which reduces the rotation speed and increases torque in order to lift the load.

The rope is fixed to the hoisting drum on one end and connected to the rope anchorage on the other. As the hoist drum rotates, the rope winds or unwinds and is guided into the correct groove of the drum, allowing the hook to raise or lower. There are two ways to stop a hoist: by releasing the up or down controls on the controller, or by activating the emergency stop button.

Contact American Crane: Your Expert, Craftsman & Partner for Hoists Today

There are many components of a hoist that work together to properly raise and lower loads within a facility. At American Crane, we offer a wide range of custom and standard hoists and hoist accessories for a diverse range of industries and applications. Our hoist options include air, electric, and manually-operated rope and chain hoists. To learn more about our products and capabilities, contact us or request a quote today. You can also check out our hoist catalog or download our Bridge Crane Lineup sheet.