Innovative Lifting in Controlled Environments

Specialized Cleanroom Cranes & Hoists for Diverse Industries

Cleanrooms refer to manufacturing environments that must remain pollutant-free to protect the safety and integrity of products. Because of this, all equipment used in a cleanroom must comply with stringent regulatory standards. This includes material handling and lifting equipment such as cranes and hoists.

Clean Room Basics

Products with sensitive production processes and components must often be manufactured in hygienic rooms free from environmental contaminants such as chemical vapors, airborne microbes, and dust. Depending on the particular application, a specific contamination threshold is set, which must be carefully maintained.

Prior to the International Standards Organization (ISO) adopting cleanroom standards, nearly all cleanrooms were regulated by FS209E, which outlines cleanliness classification levels. ISO 14644-2 specifies the type and frequency of testing needed to meet particular standards. This is the most common standard used today and is expected to eventually completely replace FS209E.

Specialized Lifting in Controlled Environments

Cleanroom Crane Applications Across Various Industries

These industries rely on American Crane’s expertise in designing and manufacturing specialized equipment that meets their specific requirements for hygienic handling. American Crane’s cleanroom cranes and hoists are designed to operate efficiently and safely in these sensitive environments.

- Electronics & Semiconductors - Providing precision handling in semiconductor production, maintaining a contaminant-free environment.

- Aerospace - Used for safe handling of aerospace components, ensuring zero contamination.

- Medical Technology - Crucial for the sterile manufacturing of medical devices and equipment.

- Pharmaceutical - Employed in handling pharmaceutical products, adhering to stringent cleanliness standards.

- Food & Beverage - Used for moving consumables, emphasizing equipment hygiene and purity.

Our equipment is built with quality materials and adheres to strict standards for safety and reliability. We utilize advanced technology to ensure optimal precision and efficiency in our products. Our team of experts is committed to providing exceptional customer support and service, making us a trusted partner for your cleanroom needs.

Precision Handling for Pristine Conditions

Specialized Material Handling Equipment for Cleanrooms by American Crane

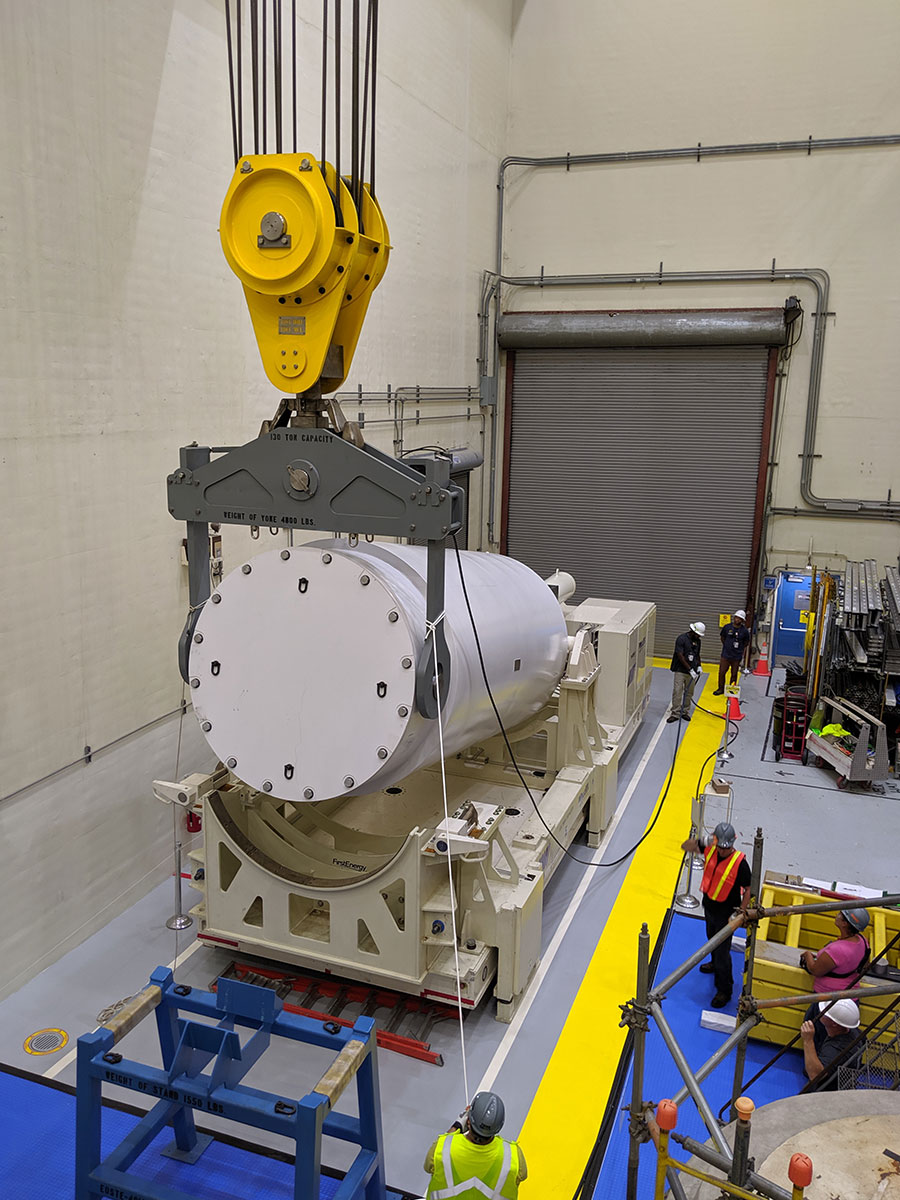

At American Crane, we can build our material handling equipment to meet the strict requirements of your cleanroom environment. Our cranes include special features and components that protect the equipment from environmental pollutants, debris, and other contaminants.

Our hoists and cranes are designed to operate safely and efficiently while maintaining an environment free from contaminants. We can manufacture equipment to meet various needs, including satellite manufacturing, semiconductor manufacturing, food and beverage applications, and more.

Other Sanitary Crane and Hoist Applications from American Crane

With in-house design and manufacturing capabilities, American Crane can provide a wide variety of cleanroom material handling solutions.

We also offer industry-leading hoist brands, including Chester, Yale, Columbus McKinnon, Coffing, and Budgit.

We can provide:

- Electric Wire Rope Hoists: We offer our own custom wire rope hoists as well as other brands.

- Air Wire Rope Hoists: These hoists allow for continual operation, with frequent start and stop cycles, while handling maximum loads up to 100 tons.

- Electric Chain Hoists: Ideal for electronic, aerospace, pharmaceutical, and food applications, electric chain hoists provide high performance across various demanding conditions.

Specialized Cranes for Aerospace Giants

American Crane’s NASA Project: Designing a Specialty Lift Crane for Aerospace

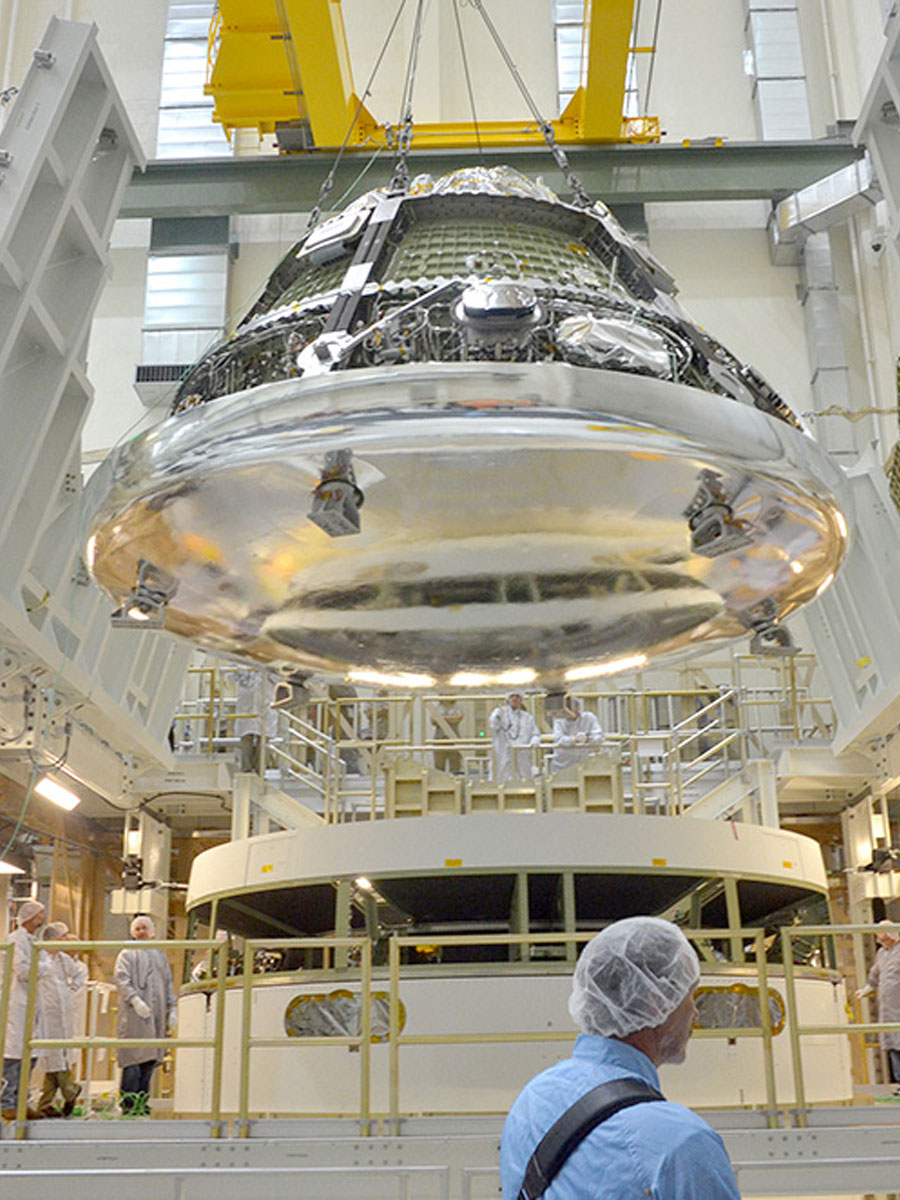

In a previous project, the National Aeronautics and Space Administration (NASA) reached out to American Crane to collaborate on the design and construction of a highly specialized and critical lift crane. The aerospace industry requires cranes that meet specific standards for handling sensitive and intricate machinery, such as spacecraft maintenance and construction, lens movement, and telescope arrangement.

To address NASA’s requirements, American Crane developed a customized 25-ton top-running double-girder crane that adhered to NASA’s stringent standards. All fasteners were constructed entirely of stainless steel and were self-locking to prevent bolts and debris from falling from the crane and compromising the cleanroom environment. Furthermore, the crane’s walkway was fitted with continuous kick plates to capture any stray debris or dirt.

American Crane’s team paid close attention to these protective features, ensuring the delivery of a high-quality lift crane that met the necessary standards. The crane was installed at the Kennedy Space Center to work on the renowned Orion spacecraft, which is widely renowned for its advanced technology and innovative capabilities.

Customized Cleanroom Lifting Solutions

Experience and Expertise in Cleanroom Cranes by American Crane

Discover the exceptional quality of American Crane’s reliable solutions for controlled handling in cleanroom environments. Our cranes and hoists are crucial for industries that require precise and contaminant-free material handling. They are manufactured to the highest standards to ensure the purity and quality of materials. Our team, with over 45 years of experience, offers premium cleanroom crane and hoist solutions, including design, fabrication, and quality assurance. For more information on our cleanroom cranes, high-performance lifting solutions, or our work with NASA, please don’t hesitate to contact us or request a quote today.