Aerospace Overhead Cranes: A Match Made for the Skies

Leave a Comment

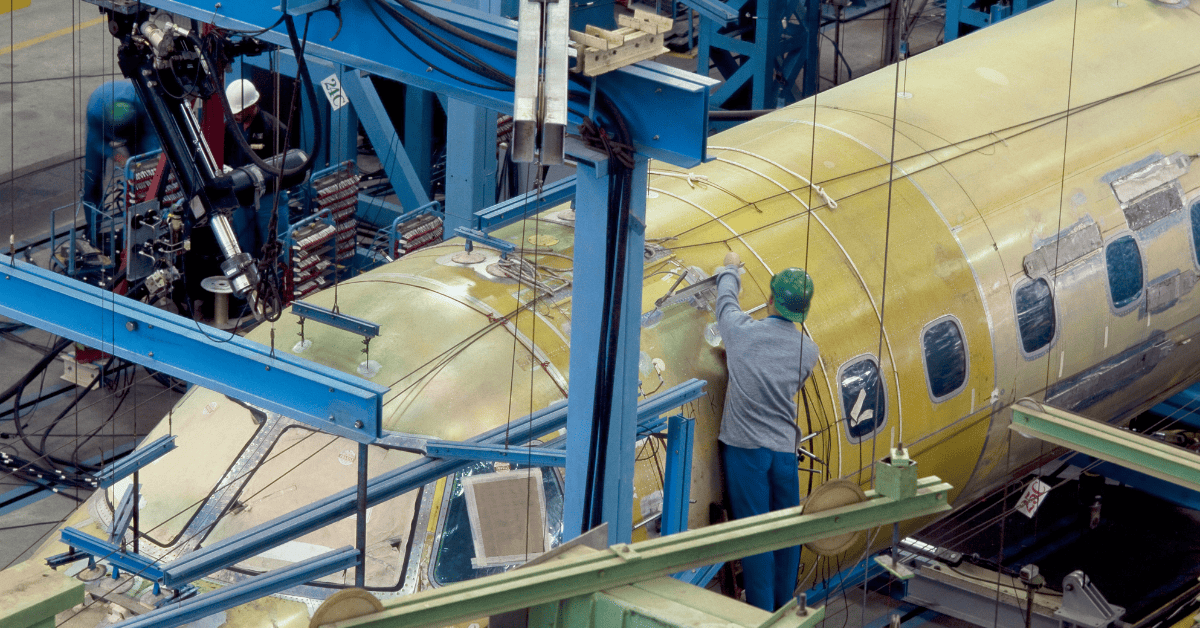

So you’re in the aerospace business, where precision, reliability, and durability are not just buzzwords but daily necessities. Let’s face it, when you’re manufacturing or maintaining anything that’s designed to take to the skies, there’s no room for error. Whether it’s assembling massive jet engines or handling sensitive composite materials, you need equipment that meets your lofty standards. That’s where aerospace overhead cranes come into play.

Why Overhead Cranes Are Crucial for Aerospace

The aerospace industry is unique—planes aren’t cars, and rockets aren’t trains. Standard material handling equipment just doesn’t cut it. Enter overhead cranes. These are not your average cranes; these are specialized systems designed for the intricate and sensitive tasks that aerospace demands. Picture this: You have a colossal jet engine that needs to be moved from one end of the warehouse to another. Sure, you could try using a forklift, but do you really want to gamble with a multi-million-dollar piece of machinery?

Material Handling You’ve Never Seen Before

An overhead crane system can easily, safely, and efficiently handle your most valuable aviation assets. We’re talking about bridge cranes that span your workspace, fitted with hoists specifically engineered for precision lifts. Say goodbye to the awkward maneuvers that come with standard material handling equipment. Overhead cranes can move smoothly along their track, carrying everything from wings to engines as if they were feather-light.

Built for Endurance and Precision

Manufacturing in aerospace means dealing with a wide range of materials and components. You’re often managing delicate composite materials one minute and robust metal alloys the next. Aerospace overhead cranes can be customized to meet the unique needs of each manufacturing stage. Hoists can be outfitted with special grips and lifts to handle the most sensitive materials, ensuring that they reach their destination in perfect condition.

No Job Too Big or Small

In aerospace, size matters. You may be assembling small drones one day and working on jumbo jets the next. Versatility is a must. With modular designs and customizable features, aerospace overhead cranes are made to adapt to your evolving needs. You can modify the track, adjust the jib, and even switch out the hoists to meet the specific requirements of any project.

Safety and Maintenance, Front and Center

Let’s not forget about the importance of regular inspection and maintenance. Aerospace overhead cranes are built for longevity, but they’re not invincible. Regular check-ups and timely maintenance ensure that your material handling systems are always in tip-top shape. After all, a faulty crane could be more than just a productivity bottleneck—it could be a safety hazard.

The Right Crane for the Right Job: Customization is Key

Choosing an aerospace overhead crane isn’t a one-size-fits-all situation. Every aviation project has its own set of challenges and requirements. Maybe you’re dealing with the tight constraints of a small workshop, or perhaps you have a sprawling manufacturing floor that’s bustling with different activities. Either way, customization is your best friend. Most overhead crane systems offer a range of options, from the type of hoist to the length of the bridge and track. This adaptability ensures you’ll have a material handling solution that fits your workspace like a glove.

Future-Proofing Your Operations

Technology is constantly evolving, especially in an industry as dynamic as aerospace. That’s why it’s essential to invest in overhead cranes that are upgradable. Whether you’re anticipating changes in material types, weight capacities, or even automation features, a modular crane system can grow alongside your business. This way, you’re not just solving today’s challenges but preparing for tomorrow’s opportunities as well.

Reducing Downtime, Maximizing Productivity

In aerospace manufacturing and maintenance, time is money. Delays in material handling can have a cascading effect, disrupting tightly coordinated schedules. Aerospace overhead cranes are designed for speed and efficiency. Their intuitive controls and high-speed hoists enable your team to move materials swiftly, cutting down on downtime and boosting overall productivity.

Why Choose American Crane?

You might be wondering, with all the options out there, why go with American Crane? Well, we bring decades of expertise and a solid track record to the table. We understand the aerospace sector’s complexities and nuances and commit to delivering robust, reliable, and tailored solutions that meet your specific needs. With American Crane, you’re not just getting a piece of equipment; you’re entering into a long-term partnership. We stand by our products and offer ongoing support, from the initial consultation to routine maintenance and inspections. Our aim is to make sure your material handling systems are always functioning at their best, so you can focus on reaching for the stars.